40KWh indoor cabinet backup power system.

| Dimensions | 1685x1035x500mm(66.3’’x40.75’’x19.68’’) |

|---|---|

| Weight | 512Kg(1128.8lb) |

| Nominal Voltage | 409.6V |

| Nominal Capacity | 100Ah |

The 40KWh lithium iron phosphate small energy storage cabinet, single cell 50AH, 2 parallel 128S, 409.6V 100AH, system consists of 16 8-series 2-parallel modules + 1 high-voltage control box + a double-door battery cabinet.

CAN2.0, RS485

From 10KWh to 2MWh

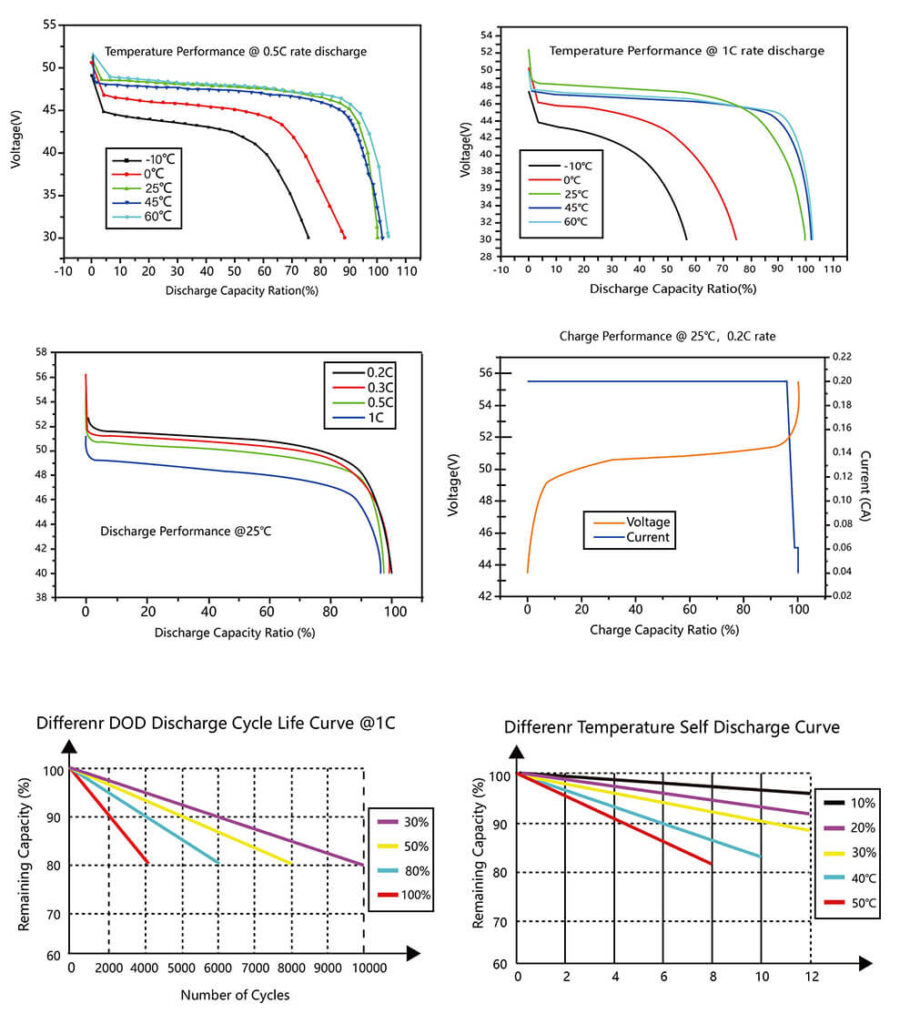

More than 6,000 cycles.

Charge: 0°C to +60°C

Discharge: -20°C to +60°C

Battery management system, referred to as BMS, is a battery management system designed and developed for the characteristics of high-capacity and large-scale energy storage battery arrays. It is the core equipment of this product. It mainly monitors and manages the status of large-scale battery arrays. And protection, to ensure that the battery is used safely, make full use of the battery storage capacity and prolong the battery life, so as to achieve the purpose of efficient use of the battery.

BMS general functions

Responsible for the corresponding management of all BMUs under a PCS, communicating with the PCS and the background monitoring system at the same time, and timely requesting PCS management according to the status of the battery pack.

The main functions are as follows: